Drill Bit Manufacturer Chooses Cybernet for Factory Floor

-

ULTERRA DRILLING TECHNOLOGIES, L.P.

- Industry: Industrial

- Product: iPC R2ix

- HQ: Forth Worth, TX

Challenge

Challenge

Few factories are neat and tidy places, but milling drillbits creates a massive amount of metal particulate and graphite dust that tends billow through the air and creep into every tiny crevice. This includes the thin-client PCs that Ulterra Drilling used constantly for tracking orders, inventory, and for guiding the entire manufacturing process.

The PCs were dying practically as fast as Ulterra could replace them — each would last only two to three months before giving up the ghost. Ulterra ended up keeping a stock of spares on stand by to swap out the computers as soon as they died. Spending $300-$400 per unit every three months became untenable.

The problem with off-the-shelf, consumer-model PCs is that they aren’t designed with hostile environments in mind. Their cooling fans sucked the graphite and metal particles right into the case, spreading conductive metal debris all over sensitive electronics.

Ulterra needed a better solution, a computer that could handle the harsh rigors of the modern manufacturing process.

Solution

Solution

Ulterra began to research "rugged industrial PCs," and eventually came upon Cybernet Manufacturing’s line of iPC models.

Ulterra's main plant in Fort Worth, Texas requested and received a pair of iPC R2ix mini rugged computers to put through their paces as demo units. When the iPCs arrived, they were immediately put to work in the unforgiving environment surrounding the drillbit mills and used around the clock by workers on the factory floor.

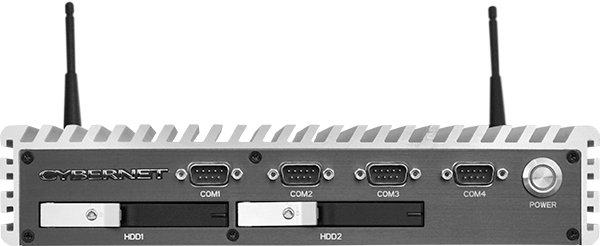

The Cybernet iPC R2ix's sealed case kept the components protected, and the fanless cooling technology prevented graphite and metal dust from being sucked right into the device. Their universal-mounting compatibility made them quick and easy to install virtually anywhere in their facilities.

Results

Results

After four months without a single glitch or hitch, Ulterra saw the immediate value add and made their decision. They ordered 20 more units right to the same facility, and would eventually order more for all of their locations.

The Cybernet iPC R2ix ran Ulterra's web-based manufacturing applications without a hiccup.

Using Microsoft's standard System Center Configuration Manager, Ulterra's could image the new Cybernet computers the way they've always done it and get the computers delivered, unpackaged, installed and working on the factory floor often in the same day.

Ulterra reported that the VESA mounting options allowed the Cybernet industrial PCs to be installed in multiple locations in different ways with no problem at all - they had to be flexible, because not every work station was exactly the same.

The Cybernet machines have since withstood the manufacturing barrage, they've reduced downtime, and they've provided an immediate ROI. The first installed units have more than paid for themselves when compared to the commercial grade units they were having to replace every two or three months. Ulterra already have plans to fill their new Canadian manufacturing plant with Cybernet's rugged industrial PCs and are upgrading their current facilities with Cybernet units as their old units fail.

Half of our manufacturing site is in Canada, and so those guys were down here and saw them and immediately said, 'we need some.' We're actually in the process of tearing out all of our old machines in our Canada sites right now and putting Cybernet's in.

- Derek Greer, Director, IT and Operations

ULTERRA DRILLING TECHNOLOGIES, L.P.